Diesel Block Counter Boring

Diesel Sleeve Counter bores - In shop and Infield counter bore services are available.

Hillside Machine Inc. On Site Counter Bore Machining Tech's have built up an extensive range of experience utilizing precision portable machining equipment. Our Field Counter Bore machining team, comprising of highly skilled technicians with many years experience in Marine, Heavy Duty and Diesel Engine counter bore equipment repairs will succeed where many others have failed. Hillside Machine's main focus is to provide accurate machining facilities on site greatly reducing equipment downtime, and increasing productivity.

After surfacing of a Diesel block, the height of the counter bores must be re-adapted to the size of the liner rims, less the amount of the protrusion. Hillside machine employees several methods:

1. AMC 2500 Boring Mill for in shop counter bore work.

2. Kwik Way , Rottler or Van Norman portable boring bars.

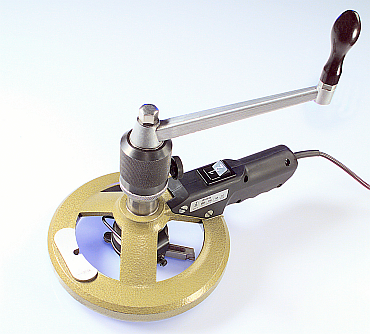

3. Portable high precision counter bore tool. In shop and Infield counter bore services second to none.

In shop and Infield Insitu Counter Bore repair and refacing.

To guarantee a perfect seal between engine block and wet liners, the counterbore seats in an engine block must be refaced during engine overhaul and in case of leaks. This job is carried out with the very accurate unit. It‘s centering is automatic and the clamped by means of an electro magnet. As the unit is placed direclty on the sealing surface of an engine block, the refaced counterbore seats will automatically be parallel with the sealing surface. The refacing procedures can be carried out on installed and as well from removed engine blocks or even built-in underfloor engines. In shop or Infield counter bore repair.

CAT 3400 UPPER COUNTER BORE REPAIR

Phone:1-781-321-9625

Portable Couter Bore utized in Instu Service

Couter Bore utilzing AMC 2500 bore mill.